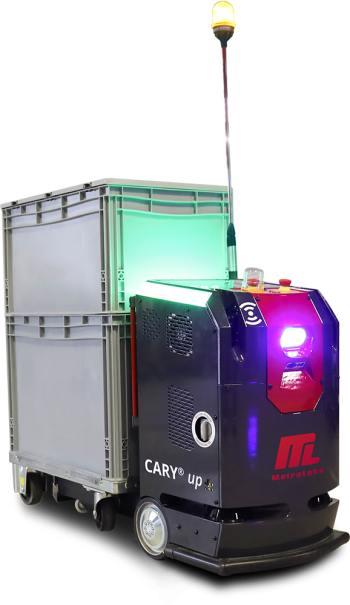

CARY® up - The AMR for intralogistics automation

CARY® up moves supplies connects

Flexibly scalable - on the move as a fleet

Our robot systems work as a fleet. This means that the transport tasks can be automatically distributed among the AMRs. If the capacity of the fleet is exhausted, any number of CARYs can simply be added. Using our fleet manager (CARY up also supports VDA 5050), the autonomous systems know exactly where they and their robot colleagues are in the production hall.

Higher capacity with lower space requirements

Many transportation tasks do not require a large, bulky conveyor system in the conventional sense. With an AMR fleet, the conveyor system is located exactly where the transport is taking place.

No changes to the infrastructure required

CARY® up transports dollies and other load carriers on the warehouse floor between storage, buffer and delivery stations completely independently. No track guidance is required. Our AMRs impress with their simple installation and, thanks to VDA 5050 compatibility, easy integration into existing WMS, intralogistics and ERP systems.

Flexibly adaptable to your needs

As a company with many years of experience, we know that there is no standard solution for many challenges and that most applications differ from one another. Accordingly, CARY® up can be adapted to your requirements, be it the type and shape of the load carrier, the software or the color scheme according to your corporate design. You benefit from customized systems.

Safety through intelligent sensor technology

To ensure the safety of our products, we integrate intelligent sensor technology into our AMRs. Together with our navigation software, the sensors ensure reliable obstacle avoidance and a high level of driving safety – so safe that nothing stands in the way of use in dynamic environments and human-robot collaboration!

- Developed for the transport of dollies & other load carriers

- Payload of up to 250 kg (~550 lbs)

- Compact Design

- Autonomous charging

- Easy to integrate into existing WMS and ERP systems - VDA5050-compatible

- Can be used as individual systems or as a fleet

- Robust design and safe navigation thanks to intelligent sensors and software und Software

- Customizable (load carrier, software, corporate design)

- Global service network

The safety drive control of the MetraLabs robots has been tested and certified by TÜV Thüringen in accordance with Machinery Directive 2006/42/EC, Annex IV, No. 21.

Request data sheet now

Request a product data sheet now and get in touch with us. We are happy to help!

More Transport Solutions

CARY® flex

Customizable Material Flow

Special processes require special solutions! There are many ways to configure the reception, transport and dellivery of SLCs.

CARY® flex can be modified in multiple ways, so its material handling fits perfectly to your production facilities. It can be used both as an active and passive load suspension device.

CARY® light

Small goods, long ways

After an order is placed via tablet, CARY® light transports the required parts from the warehouse and takes them to the desired production location. This AMR is the perfect small parts supplier for assembly stations or quality management.

Custom Solutions

Application-Specific Mobile Robots

For specialized requirements, we develop customized solutions that go beyond standard products. Hardware, software, and interfaces are precisely adapted to your application, environment, and processes.